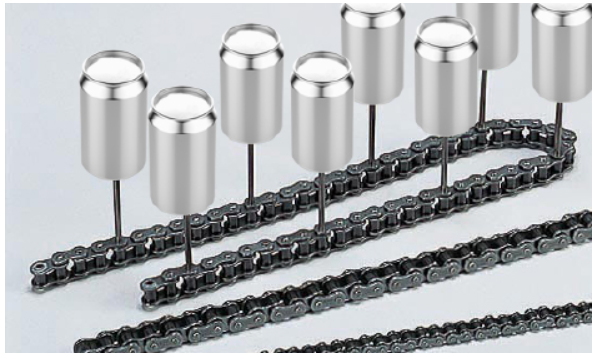

DID industrial roller chain, especially our DID Pin Oven Chain, is engineered to perform exceptionally well inside high-temperature ovens used in can manufacturing lines. Often referred to as “Deco Chain,” this specialized chain ensures smooth and reliable conveying of decorated and base-coated cans through high-speed, high-heat processes.

Trusted across Japan, the DID Pin Oven Chain dominates the domestic market due to its excellent long-life performance, superior stability, and minimal maintenance needs.

✅ Key Benefits of DID Pin Oven Chain

-

Wide Clearance

The wide gap between outer and inner plates enables lubricant to efficiently reach pins and bushings, reducing chain stretch. -

Reduced Lubrication Needs

Efficient lubrication minimizes sludge and fume contamination, keeping both the chain and cans cleaner. -

Polished Surface

Both outer and inner plates are mirror-polished, allowing for easier cleaning and better hygiene in food-grade operations. -

Stable Long Pins

Extended contact area between pins and bushings ensures low vibration and high durability under continuous operation. -

Easy Pin Replacement (LP Type)

Non-riveted LP-type pins with spring clips and plastic tips can be replaced quickly in case of damage.

⚙️ Product Example: DID 60LD SSP X-ring Pin Chain

-

Tensile Strength: 32.4kN Minimum

-

Assembly Configuration: 504LZ × PCS

-

Connection Link: Slip-fit LP with plastic tip

-

Extended Bushing Design: Improves clearance and stability

-

X-ring Type Available: Enhanced sealing for high-heat environments

📂 Available Options

-

Multiple chain sizes and configurations

-

Variety of pin tip designs

-

X-ring sealing options for added heat resistance

-

Custom designs available on request